Activation status

Please contact Vertiv Partner Support: salescloudsupport@vertivco.com

Working with our Vertiv Sales team enables complex designs to be configured to your unique needs. If you are an organization seeking technical guidance on a large project, Vertiv can provide the support you require.

Many customers work with a Vertiv reseller partner to buy Vertiv products for their IT applications. Partners have extensive training and experience, and are uniquely positioned to specify, sell and support entire IT and infrastructure solutions with Vertiv products.

Already know what you need? Want the convenience of online purchase and shipping? Certain categories of Vertiv products can be purchased through an online reseller.

Need help choosing a product? Speak with a highly qualified Vertiv Specialist who will help guide you to the solution that is right for you.

Cookies Settings

Technical Cookies

These cookies are essential to ensure the correct functioning of the website, to allow you to register/login and access reserved features, and to allow us to monitor the security of the website and improve operating performance, for example, by storing your preferences to enhance your subsequent visits.

Analytics Cookies

These cookies allow us to collect and analyze traffic and use of the website on an anonymous basis and to understand and improve how visitors use the website, including which pages and products are viewed most frequently. These cookies are not strictly necessary for the website to work but will provide you a better browsing experience.

Profiling Cookies

These cookies allow us to track your navigation of the website to create profiles of your tastes, habits, choices, etc., to send you promotional messages targeted to your preferences. Refusal of these cookies will not affect the proper functioning of the website but will prevent us from being able to send your promotional messages targeted to your preferences.

By clicking “Accept All”, you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

For more information on which cookies we use, click here.

For more information on which cookies we use, click here.

-

Home

- Solve Problems Before They Start

Solve Problems Before They Start

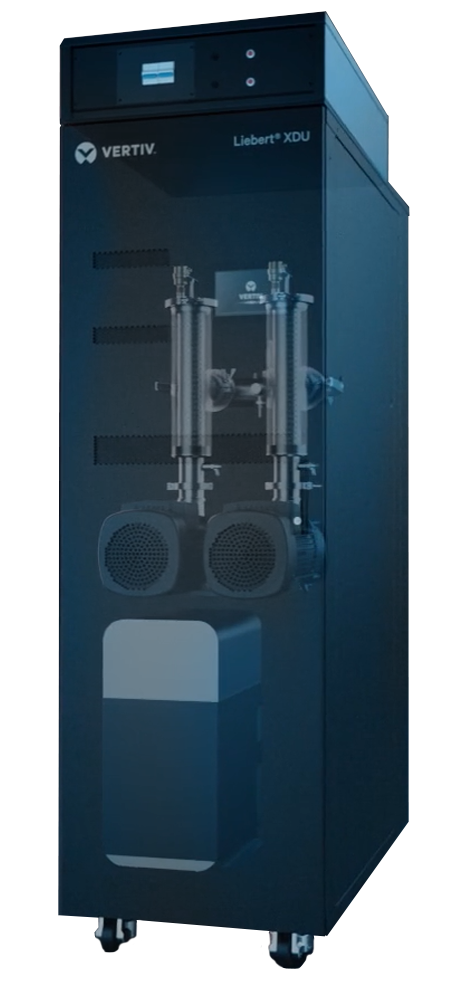

The Vertiv™ Liebert® XDU, our next generation of liquid cooling technology, is designed to seamlessly fit into your IT environment, engineered to reliably and efficiently manage your high-density thermal loads.

Designed to support liquid cooling within high density environments, the Liebert® XDU Coolant Distribution Units are suitable for chip & rear door cooling applications that offer easy, cost-effective deployment in any data center. The Liebert XDU family offers systems that operate with/without facility water, allowing you to tap into the benefits of liquid-cooled servers to more efficiently support higher rack densities without incurring the costs of major infrastructure changes.

What are the benefits and features of the Liebert XDU

Click the buttons below to learn its features.

Supports rear-door heat exchange, or Direct Contact Liquid Cooling to manage power-dense hot spots up to 450 kW or 1368kw of heat

Compact Footprint allows for either end of row or perimeter placement

Local Touchscreen Display provides real time visibility and advanced monitoring, and alerts

Coolant Distribution Unit (CDU) features an innovative, stainless steel fluids circuit design to provide essential separation of the primary facility water from the ITE heat load

Built in 50-Micron Filtration Unit keeps the secondary fluid network free from debris and contaminants

Redundancy: N+N pumps, inverters, expansion vessels, pressure & temperature sensors for built-in redundancy

Dual Power Feed (optional)

Insights

Contact Us

Fill out our form and we will contact you to discuss your liquid cooling needs.

Thank you! Submission has been successfully sent.