Providing Unmatched Protection of Critical Manufacturing Assets

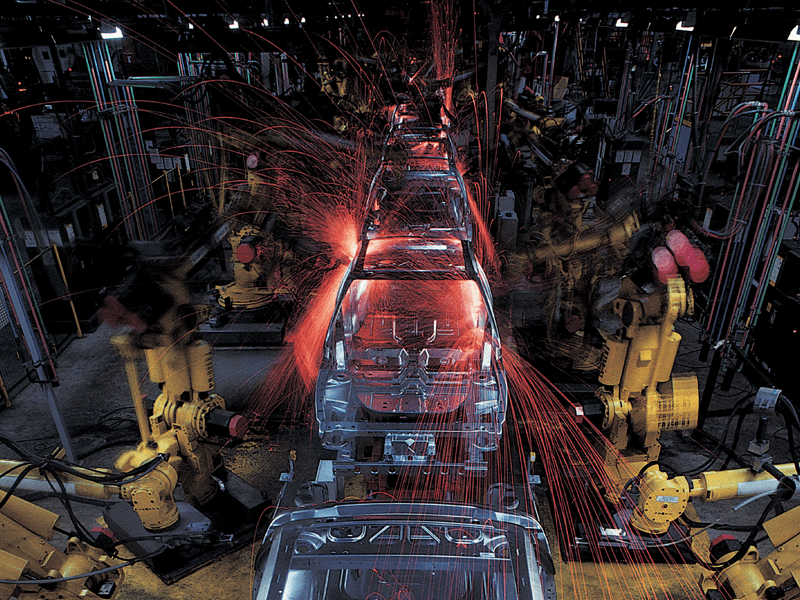

Vertiv in Manufacturing: We're at the age of Manufacturing 4.0 with Artificial Intelligence, Robots and 'smart' technologies are transforming the factory floor. Is your business ready?

Welcome to Manufacturing 4.0

Al takes

Center Stage

- To improve processes, manufacturers are increasingly eyeing investments in automation such as robotics and machine learning.

- Research & market expect AI spend in manufacturing to reach $17.2B by 2025, growing at a CAGR of 49.5%.

- A key benefit in automation is that it reduces risks especially in industrial sites such as those using heavy machinery or those in dangerous operating environments.

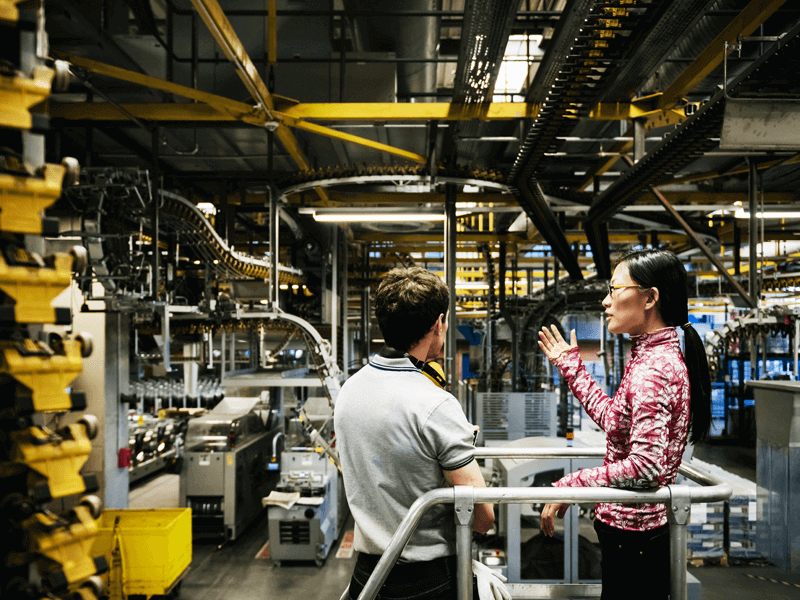

A Leaner Supply

Chain System

- To stay above the competition, an organization’s supply chain needs to be optimized to deliver greater value to customers.

- Aside from pricing and stock availability, manufacturers will increasingly focus on simplifying supply chain management to be able to operate more efficiently, manage stocks better and reduce operational cost.

- Many will digitize their supply chains through the use of RFID, business intelligence, as well as tools to improve logistics, optimize network and inventory, and procurement.

Predictive Maintenance

Gains Traction

- There is growing adoption of predictive maintenance technologies that could not only reduce a company’s maintenance cost but also avert unplanned outages and extend equipment life.

- The use of predictive maintenance tools to monitor equipment performance, as well as integration of IoT and automation, could save manufacturers valuable time, money and resources.

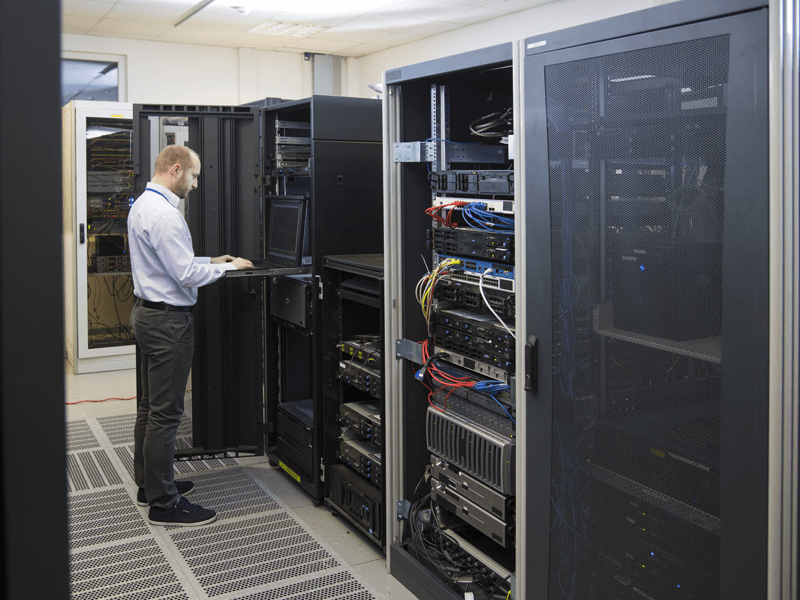

Infrastructure Challenges

- Growing customer demands and expectations are putting pressure on manufacturers to make sure they meet or even exceed production schedules.

- Protection of manufacturing equipment is critical, as downtime means lost productivity, penalties, damaged reputation and lost revenues.

- There are many causes of downtime, but many equipment-related failures can be preventable.

- Therefore, it is important to maintain reliability through regular facility testing and by utilizing solutions that protect against common causes of breakdowns such as power surges and electrical spikes.

- With increased reliance on automation and artificial intelligence, manufacturers must be able to come up with ways to seamlessly integrate technology into everyday manufacturing operations.

- AI and robotics are increasingly being used on the manufacturing floor to speed up manufacturing processes.

- Manufacturing equipment should be optimized and designed to accommodate technology integration through the use of predictive tools as well as power availability.

- Digitization and automation are increasingly being adopted by manufacturers to improve efficiency and overall operations.

- Manufacturers must be able to come up with ways to seamlessly integrate technology into everyday manufacturing operations.

- Equipment should be optimized and designed to accommodate technology integration through the use of predictive tools as well as power availability.

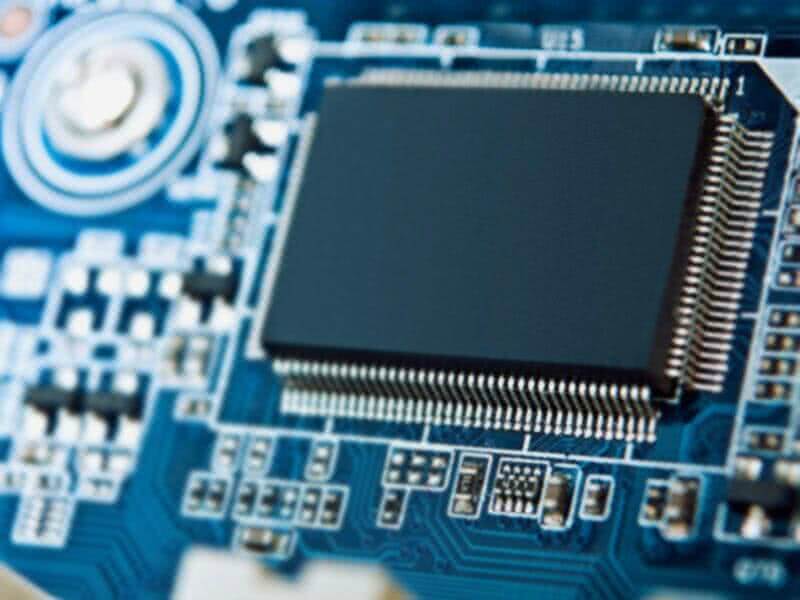

- IT infrastructure becomes all the more critical in the age of automation and IoT, and IT managers must have the right infrastructure in place not only to support the uptick in compute requirements, but also to manage the entire manufacturing facility better and smarter.

- The use of Artificial Intelligence (AI), Machine Learning (ML) & Robotics in manufacturing means an uptick in computing power and demand. Necessary solutions that are rugged and efficient are critical to support corporate demands in a manufacturing environment.

- As they strive to create a leaner, more efficient supply chain systems, manufacturers need to be aware of key supply and demand information in real time, right up to the shop floor – to be able to adjust production SKUs and schedules.

- A facility or IT manager will need to be able to see a problem before it becomes a problem – and be able to do something about it.

- Predictive monitoring tools can aid in having a smarter supply chain network. These tools must be able to predict, diagnose and provide action on all areas of the manufacturing network (from the environment, equipment or IT network) to ensure process continuity at all times.

Vertiv in Manufacturing Floor

Reliability & Availability across the Manufacturing Floor

| Data Center with Special Requirements | Utility Room |

| Network Branch Office | Lab Test Facility |

| Factory Floor | Precision Tools Protection and Process Continuity |

Manufacturing Sub Industries

Vertiv solutions help transform different manufacturing processes to improve productivity and profitability while increasing scalability.

Featured Case Studies

Global Automotive Manufacturer

7월 14, 2017This global automotive manufacturer has a strong presence in Malaysia and Southeast Asia. Through Vertiv’s SmartRow™ solution, the customer was able to achieve the highest levels of availability and scalability in its new data centre site...

자세히 보기 See all ArticlesTALK TO ONE OF OUR VERTIV EXPERTS TODAY

Related Articles